3d Scanner Basics for Reverse Design

Have you ever before found out about these 3d scanners? They are the contemporary variation of the coin cam. You have seen those coin video cameras that can be used to scan coins at coin shows and also events. These coin electronic cameras are typically furnished with a laser that can be aimed directly at the things that you wish to check. The laser will then generate a reflection in the lens of the 3d scanner to ensure that you can see your photo on the item that you are scanning.

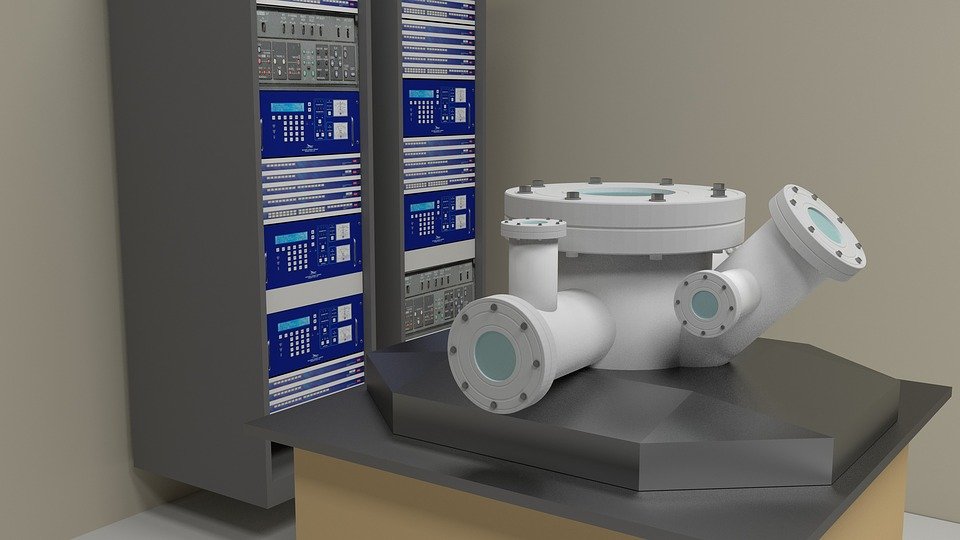

Handheld 3d scanners are not as well expensive, however they are worth the financial investment for those that are major collection agencies of things or of various other valuable things. One kind of 3d scanner is the x 200 3d scanner. This sort of 3d scanner works by utilizing an organized light to emit light onto the object that you intend to check. The x 200 can additionally work with any type of sort of computer. It functions particularly well when scanning items that go to least three inches lengthy or much less in height. The following kind of 3d scanners available is the laser pulse x 200. This sort of 3d scanner works in a comparable style as the x 200, except that it is capable of scanning items that are 3 inches in height or less. It does, nevertheless, have a more effective laser pulse.

There are many other types of 3d scanners that can be made use of for scanning. A few of them have different functions such as image stablizing, numerous zones of coverage, high contrast and also high resolution, and also the capability to check lots of applications at once. Other sorts of 3d scanners can scanning objects that go to least three inches in elevation or smaller, and also might be capable of scanning items that are 2 inches or much less in height. 3d scanners can be made use of in the field of reverse design. When you use a 3d scanner in this capacity, it is important that you recognize what your options remain in order to make the most reliable use of the tools. Numerous companies buy the appropriate type of laser and then utilize it combined with software program to check different kinds of hard to get to locations of info that is needed for reverse engineering work.

This method not just enables the company to conserve beneficial time however likewise results in less lost sources that can be spent on even more rewarding ventures. One point that should constantly be remembered when working with laser 3d scanners in a reverse design capability is that one factor is all that you will ever need to check. In order to produce something that is smaller, typically less than a quarter of an inch, a smaller sized laser scanner will certainly be required. A bigger one will be required if one wants to scan an item that mores than a quarter of an inch in dimension. It is for these factors that small firms that are just able to pay for a solitary point laser scanner in their arsenal will certainly many times go with one point instead of investing the money on a two or three-point system that would certainly allow them to check multiple things at once. Check out this related post to get more enlightened on the topic: https://en.wikipedia.org/wiki/Structured-light_3D_scanner.